Simulation using ANSYS Professional NLS helps to reduce Product Development Cycle

Case Highlights: Client :

- The customer is a leading Infocomm Solution provider having verticals in Oil and Gas, Infocom, Fiber Optics etc.

- This particular division is into the Designing and manufacturing of Splicing Structure for Fiber Optics.

Technology / Software Used: ANSYS v14.5 Professional NLS

Business Requirements / Challenges:

- To simulate wide number of tests for Splice Structure used for splicing of Fiber Optics

- In case of development of Splicing structure, it is essential that the product should pass various Tests ranging from Shock loading to Impact.

- With these expectations, it becomes essential to focus on designs which can be readily used with fewer number of prototype testing.

Solution:

- The software used to perform analysis was ANSYS v14.5 Professional NLS.

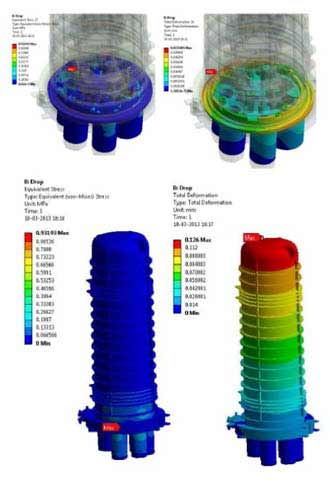

- A 3D Assembly model of Splice Structure was created and analyzed for Various Tests: Shock Loading, Impact Loading (Equivalent Static Loading), Temperature Loading etc.

- The analysis was performed to determine whether the structure will withstand the Tests performed.

Benefits:

- Assessment by FEA methodology shortened the Product Development Cycle by significant amount.