Misconceptions Related to Good Mesh and Their Realities

Posted by Bhaumik Dave on September 16th, 2013

Meshing has been and will always be an important task for CAE users. There has always been an emphasis on creating high quality mesh generation while performing FEA.

Hence; it becomes very important to recognize the importance of quality mesh in finite element analysis activities. But the most important aspect that becomes the determining factor is the inquisitiveness of outlining the quality of good mesh.

To make it unpretentious it is very important to read the output of mesh quality report in your meshing software. This is the only parameter that can provide you with appropriate answers as to whether the mesh generated is good or not for physical problem. But there are lots of misconceptions related to good mesh and unfortunately it is quite difficult to gauge the effectiveness of the mesh because there is no course that can guarantee good meshing solutions.

Hence; it is not surprising to note that there are lots of misconceptions related to good mesh in the minds of CAE users. Let us look at these misconceptions along with the realities associated with them:

Misconception: Good mesh and CAD model go hand-in-hand

Reality: This is not true as good mesh and CAD model do not necessarily yield positive results. Good mesh is a consequence of resolve physics, and does not principally stream CAD model.

CAE simulations are useful to get results relating to physical quantities including: stress, displacement, velocity, and pressure. CAD model gives a notion of physical objects. But lot of the analysis that is done does not serve the purpose and has marginal impact on the calculation.

Hence; knowledge of physics in the system is very important and a good mesh should be able to simplify CAD model. Hence, you can generate good mesh only if you know the physics in your system.

Misconception: Good mesh is always of good value

Reality: There are times when CAE users try to oversimplify the entire process of mesh generation and end up over doing it. This is since good mesh is the consequence of physic problem to be simulated. Always remember that a good member will always be associated with physics.

So, when you alter the boundary conditions or load conditions a good mesh for numerous causes may turn into bad mesh. Hence; lot of careful activities need to be carried out in order to make sure that you get a good mesh.

Misconception: Hexahedron is always better than tetrahedron

Reality: This was true about 15 to 20 years ago but with times this has changed. Now accuracy advantage of hex mesh no longer exists for most engineering problems.

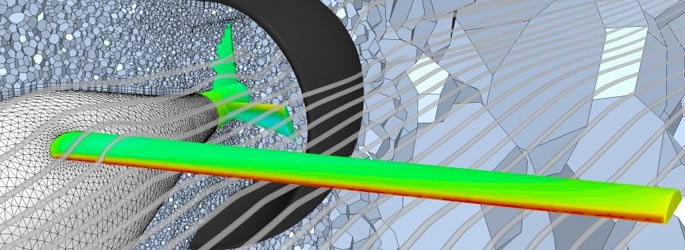

For some special applications like wind turbine, pump or aeroplane; hex mesh is still preferred because it is industry conception, it has well-understood physics, and consists of special tools to generate hex mesh for these types of geometries.

But for FEA and CFD users, if the geometry is somewhat intricate, it is wastage of time to go for hex meshing. Most of the times; we realize that mesh generation is not better, and the time saved with hex mesh is marginal in comparison to time wasted in mesh generation.

For any FEA related queries email us at : info@hitechfea.com or contact us.