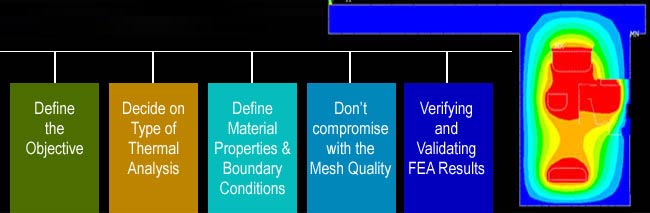

5 Tips to Help You Successfully Perform Thermal Analysis Using FEA

Posted by Bhaumik Dave on November 5th, 2014

Thermal analysis is the second most common analysis performed by engineers to evaluate the product design involving the generation, storage or exchange of heat. While this analysis plays a crucial role in identifying the effects of temperature on the product geometry, the accuracy with which these benefits are actually applicable for improving the product performance is at stake. This is mainly due to considerable number of snags present, which if not taken care of, can lead to altogether different results than what actually has been expected. To effectively streamline the procedure for thermal analysis, here’s a list of points you should follow to avoid pitfalls while performing thermal analysis using finite element approach.

Define the Objective:

The very first requirement prior to thermal analysis is to have clarity of the objective. The entire analysis procedure will be based upon the defined objective. While thermal analysis is primarily performed to calculate temperature, temperature difference, heat flux and heat transfer rate for a given geometry; it is important to define what is actually desired for the existing case or project. Is it sufficient to have temperature distribution data or the effect of thermal stress is also to be considered? Is there a need to couple the thermal analysis data to structural analysis? Does the temperature vary with time or only the initial and end states are of prime interest? By asking these preliminary questions, the problem becomes much simpler and the chances of deviation in the results reduces significantly, since there is a definite objective of what actually needs to be done.

Decide on Type of Thermal Analysis to be Performed:

Defining the objective will help you realize the type of thermal analysis required to be performed, i.e. transient or steady-state. In case were temperature is a function of time, transient analysis is required. Whereas, steady-state analysis is performed when the heat load is steady or its variance with time is almost negligible. Usually, even in the case of transient analysis, it is preferable to perform steady-state analysis first to obtain initial conditions. Moreover, with transient analysis, there has to be proper time-stepping and load-stepping strategy. Too small time steps can cause numerical errors in the solver, and the solution may not initialize.

Define Material Properties and Boundary Conditions:

To maintain the result accuracy, material properties and boundary conditions are of a crucial interest. Replicating real-world conditions within the finite element model will yield much expected and meaningful results. This requires identifying whether the material is linear or non-linear (i.e. whether the properties change with change in temperature). While most materials are non-linear in nature, linear analysis is applicable for small geometries where temperature is assumed to remain uniform. However, in cases were radiation is also involved, the analysis becomes essentially non-linear; requiring to take into account the latent heat load as well. Additionally, specifying boundary conditions accurately is a major requirement to assure expected results. In case of thermal analysis, the effects of convection or radiation also must not be neglected, if the project involves these modes of heat transfer.

Don’t compromise with the Mesh Quality:

The results of finite element analysis are dependent on the quality of mesh applied on the geometry. While analysts often try to minimize the use of computational power to save simulation time, the mesh quality is often compromised. This yields to an inadequate capturing of the physics and subsequent deviations from the expected results. In fact, regions such as edges, contact surfaces or complex regions are required to have finer mesh, in order to determine proper thermal distribution.

Verifying and Validating FEA Results:

FEA results without validation are of no practical interest. It is highly important to verify and validate the results obtained through the finite element model with that of the mathematical model. The theoretical calculations will assist in validating the accuracy of the FEA solver and also verify that the results are free from any discretization error. However, FEA results must not be taken for granted simply with the numerical verification, its physical validation is equally essential and must be encouraged whenever possible.